PRODUCTS

Products from Kuppler stand for the highest quality Made in Germany.

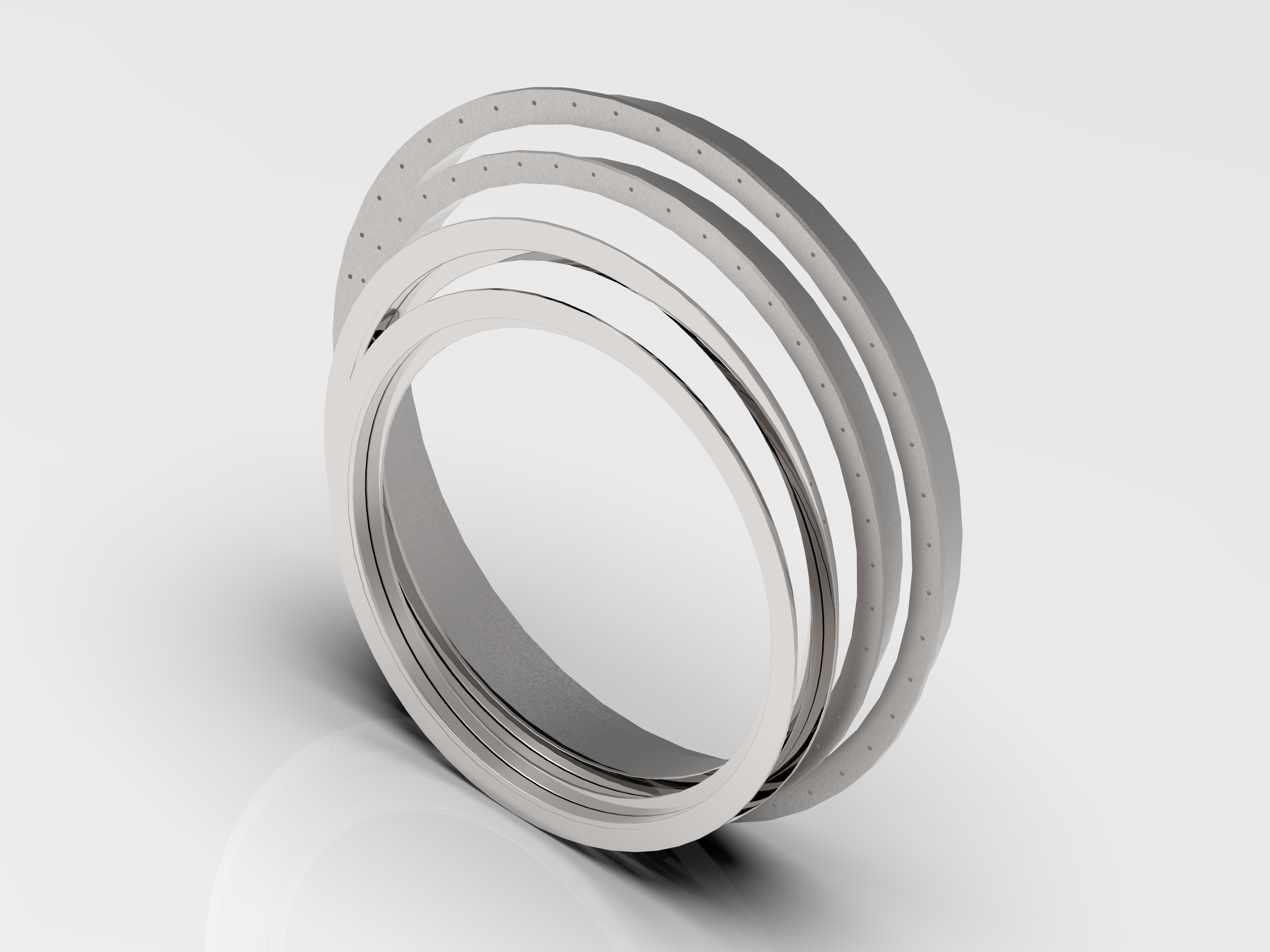

Numerous designs are available for a wide range of requirements in different industries, so that the optimal solution can be offered to our customers, both technically and economically. The robust and precise slewing bearings can be supplied as single and double row four-point bearings with internal, external or without teeth. The diameter can be freely selected from 400 mm to 4,000 mm.

All products are manufactured from high-quality, seamlessly rolled rings in accordance with the latest design and manufacturing standards and are continuously checked for specified quality standards.

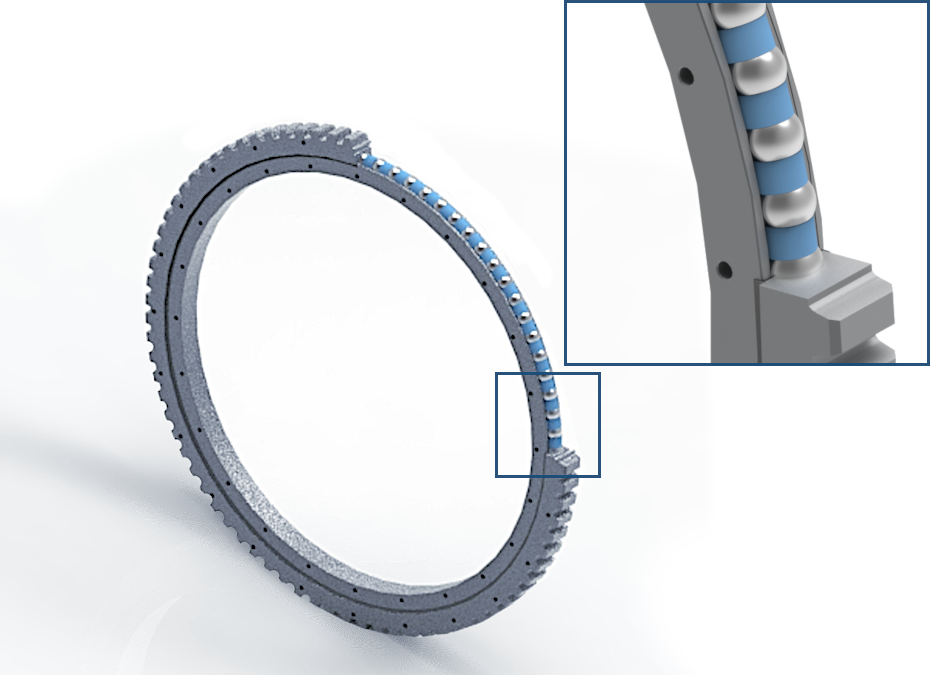

SINGLE ROW SLEWING BEARINGS

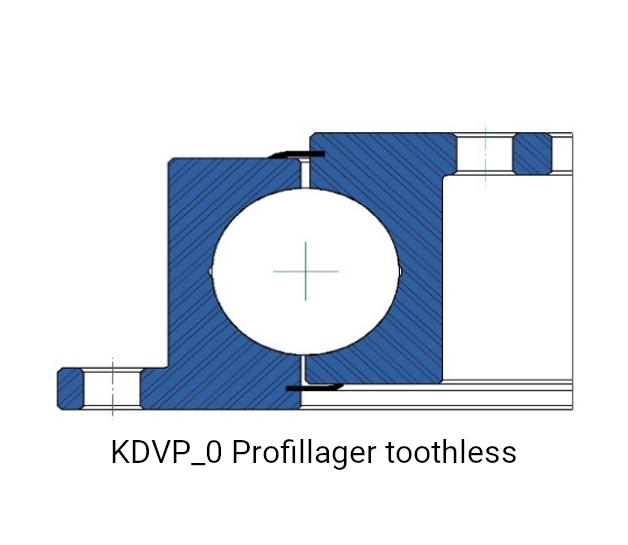

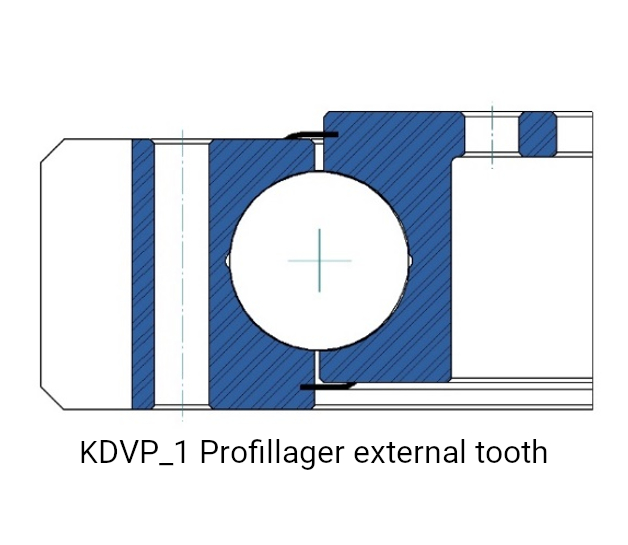

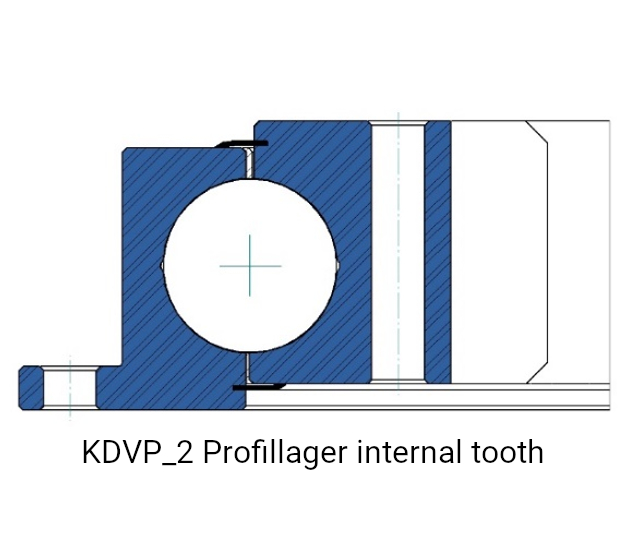

Our profile bearings are the economical solution for standard applications with moderate loads and medium accuracy requirements.

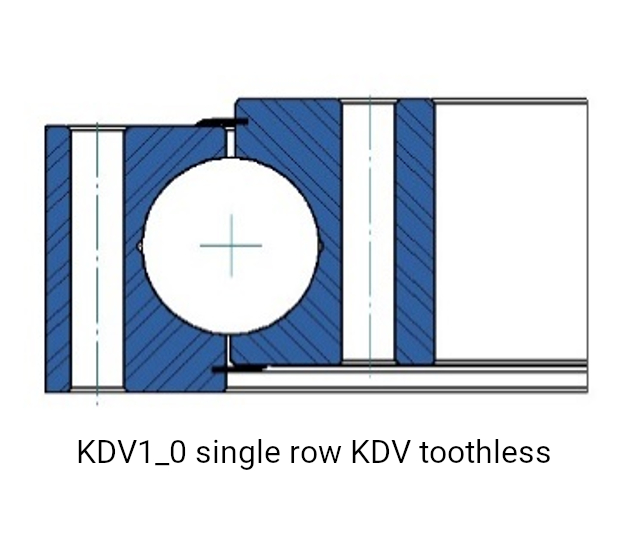

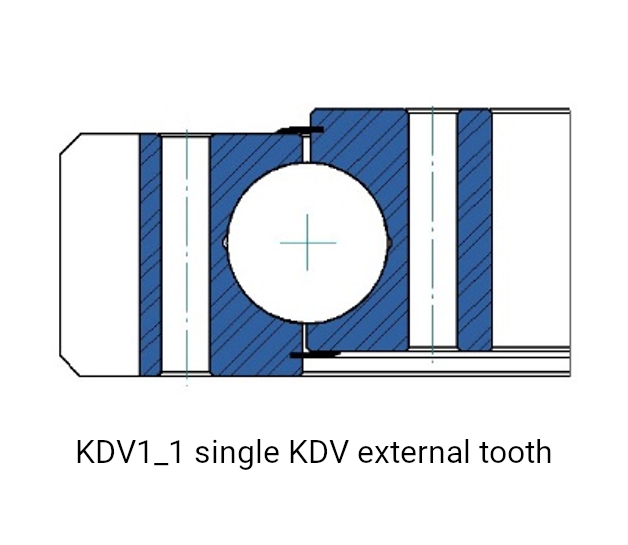

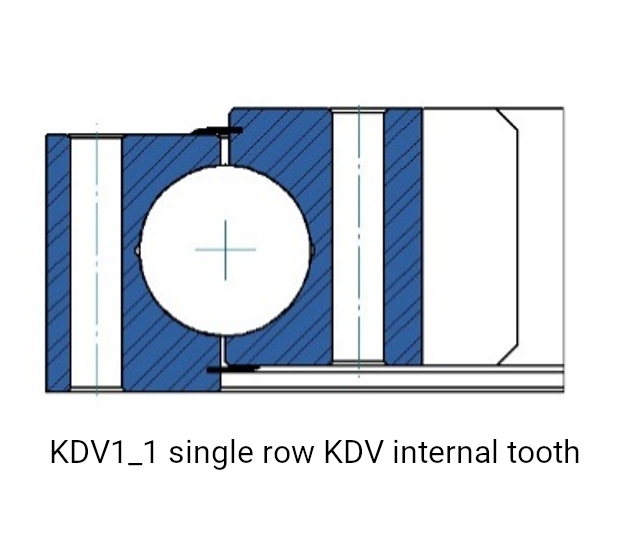

These are designed as single-row four-point bearings and are characterized by lower demands on the adjacent construction. They are available with external, internal or without teeth.

The toothless rings are designed as a profile ring, which has a positive effect on weight and costs.

Profile bearings are typically used in light cranes and construction machinery as well as swivel devices in vehicle technology and in general mechanical engineering.

Our single row slewing bearings are designed as four-point bearings and are suitable for high static loads and robust operating conditions. The KDV1 series is available in versions with external, internal or without teeth.

Typical areas of application are medium-sized cranes and construction machinery, machine and plant construction, vehicle and military technology as well as wind power.

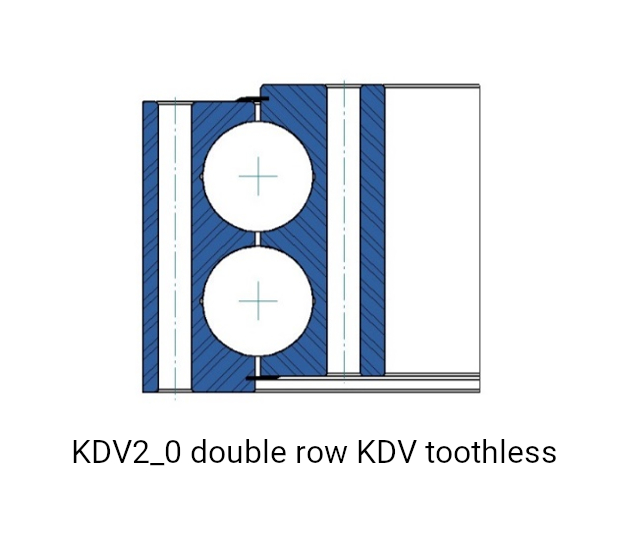

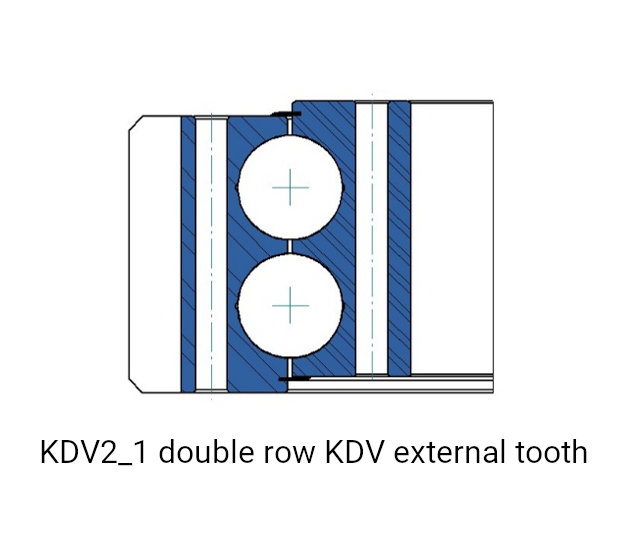

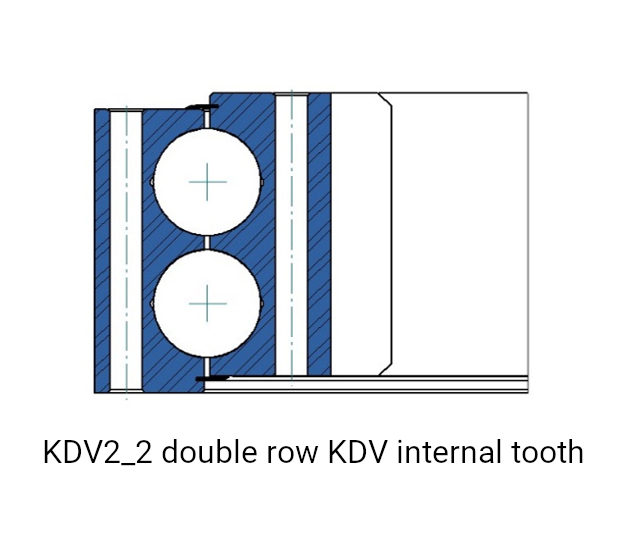

DOUBLE ROW SLEWING BEARINGS

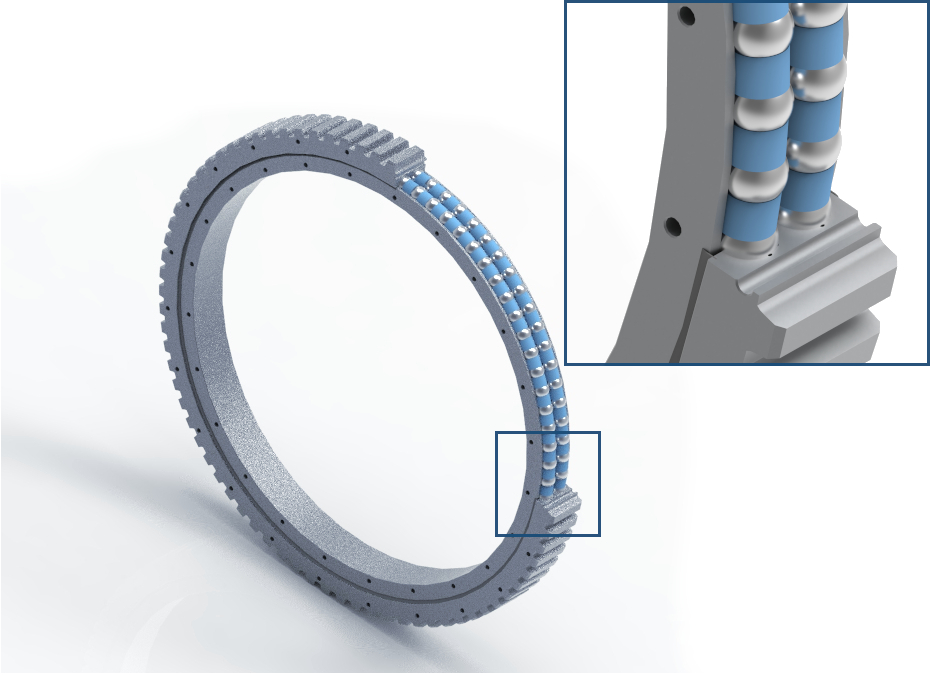

The double row slewing bearings from Kuppler are characterized by their robust design and are suitable for high static and dynamic loads.

They are designed as eight-point bearings as standard and are available with external, internal or without teeth.

Frequent areas of application for double row slewing bearings are tunnel technology, handling technology and wind power.

PRODUCTION PARTS

Whether accessories such as flanges, gear rims and pinions or manufacturing components such as turntables. In this case the design is also tailor-made for the specific application and construction and steel quality depends on the loads and area of application.

For you this means less coordination effort by a contact person and thus more time to concentrate on your actual core business.

Get in touch with us so that we can find out together what added value we can offer you.

OVERHAUL OF SLEWING BEARINGS

If your existing slewing bearing is in a condition that allows it to be overhauled, we can offer you this worthwhile option. You can send us an inquiry for the general overhaul of your slewing bearing using our inquiry form.

The general overhaul includes the following areas, depending on the need:

o Manufacture of replacement rings

o Replacement of the rolling elements

o Repair of the gearing

o Replacement of ball cages and seals

o Initial greasing of the overhauled slewing bearing